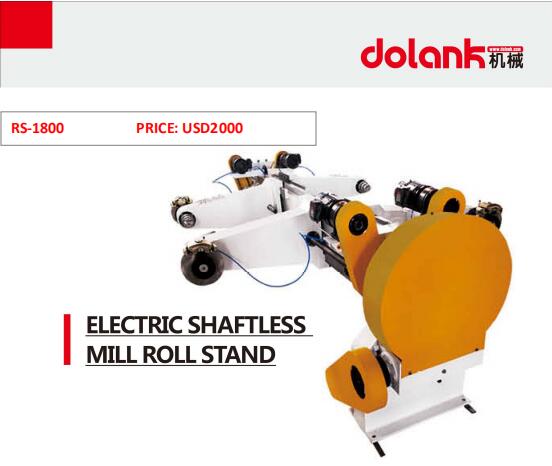

PRICE: USD7000

- 采用罩吸式结构,配高压强力风机。吸风配消音装置,气源及电气控制集中于同一操作柜,距离主机不小于1.5米,操作侧全封闭全罩。Adopt hood suction structure, with high pressure strong fan.Suction air with muffler, air source and electrical control concentrated in the same operation cabinet, distance from the host is not less than 1.5m, the operation side of the whole closed cover.

- 墙板铸铁结构,墙板厚度130mm。Wallboard cast iron structure, wallboard thickness of 130mm.

- 瓦楞辊材质采用48CrMo合金钢,经调质、中频淬火,表面磨光,瓦楞主辊直径¢ 280mm,表面硬度HRC58度以上。关键部位瓦辊、压力辊轴承采用瓦房店产耐高温轴承。Taken the corrugated roller material is made of 48 crmo alloy steel, after tempering, medium frequency quenching, surface polishing, corrugated roller diameter ¢280 mm, surface hardness HRC58 degrees above.Key parts of the tile roller, pressure roller bearing using wafangdian production of high temperature bearing.

- 压力辊¢ 292mm,表面磨削加工并镀铬处理;气缸控制上下移动,材料为中碳钢45号、调质处理(带缓冲装置)。Taken the pressure roller ¢292 mm, surface grinding and chrome plated treatment;Cylinder control up and down movement, material for carbon steel 45, conditioning treatment (with buffer device).

- 气动控制给胶退胶,涂胶辊直径¢216mm表面经磨光后刻有25线凹坑式网纹加工后镀硬铬处理,刮胶辊表面经磨光后镀硬铬处理。Taken the pneumatic control to glue back glue, glue spreader with 25 ¢216 mm diameter surface after polishing line after pit type checker processing hard chromium plating processing, scraping the rubber roller surface after grinding hard chromium plating processing.

- 瓦楞辊、压力辊原材料由中原特钢提供,瓦楞辊单边0.15mm上中高,压力辊单边0.075mm中高。加限位装置。压紧气缸用¢ 160mm气缸。Corrugated roll, pressure roll raw materials from the central plains special steel, corrugated roll side 0.15mm on the high, pressure roll side 0.075mm high.Add limit device.Cylinder pressure cylinder with a ¢160 mm.

- 预热辊采用天钢产无缝钢管¢ 320mm,。Taken the preheat roll using days steel seamless steel tube production ¢320 mm,.