Technical parameters:

| No | Item | Model:480×2300 |

| 1 | 经济速度Economic speed | 40-60pcs/min |

| 2 | 最大过纸Max. Feeding size | 1400mm×2500mm |

| 3 | 最大印刷Max. Printing size | 1400mm×2200mm |

| 4 | 墙板内径Wallboard inner width | 2500mm |

| 5 | 适合纸板厚度 Suitable cardboard thickness | 1.2-12mm |

| 6 | 主电机功率Main motor power | 5.5Kw two colors |

| 7 | 套色精度colors precision | ±0.5 |

| 8 | 开槽精度die slotting precision | ±1 |

| 9 | 机器尺寸machine size(mm) | 3500x2400x1650 |

| 10 | 重量 weight | 6900kg |

主要机械特性:Main mechanical characteristics:

该产品能一次性完成纸板的双色印刷、分切、压痕、修边、开槽等多道工序。本机整机相位调整通过数显电动调整,自动归零,自动复位;传动齿轮采用优质合金钢,材质渗碳淬火,精磨加工;主传动齿轮和传动轴采用涨紧免键联接方式,使虚位放大,取消了中心的磨损,使印刷机保持长寿命的套印精度;整机采用电动分合,气动锁紧,单机结合紧密,套印不走位;该机具有套色准确,印刷图案精美,使用和维修方便,自动化程度较高等特点。

This product can complete the two-color printing, cutting, indentation, trimming, slotting and other processes of cardboard at one time.The whole machine phase adjustment through digital display electric adjustment, automatic zero, automatic reset;Transmission gear with high quality alloy steel, material carburizing quenching, grinding processing;The main transmission gear and transmission shaft are connected by tension free key to enlarge the virtual position, eliminate the wear of the center and maintain the overprinter’s long-life overprinter precision.The whole machine adopts electric separation, pneumatic locking, single machine combination is close, overprinter is not out of position;This machine has the characteristics of accurate color register, exquisite printing pattern, convenient use and maintenance, high degree of automation.

送纸部

| 项 目item | 说 明 Notes |

| 1送纸部 Feeding part | 1.手动链条式送纸chain feeding by hand. 2.链轨采用高强度工程塑料,噪音低,经久耐用。 The link rail is made of high strength engineering plastics, with low noise and durability. |

印刷部 printing unit

| 项 目 | 说 明 |

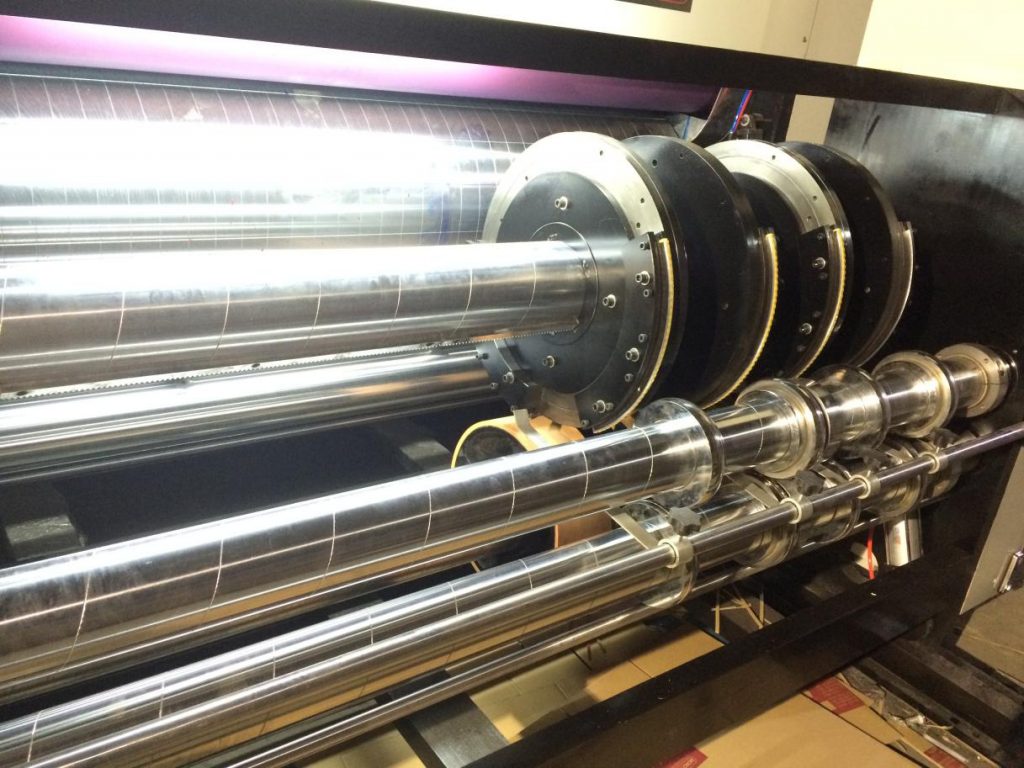

| 1印刷辊 Printing roller (版辊) | 1)外径为Ø480mm(含版外径尺寸)。 2)钢管表面研磨,镀硬铬 3)做平衡校正,运转平稳。 4)棘轮固定式卷版轴。 1) diameter for Ø 480 mm (including outer diameter size). 2) steel tube surface grinding, hard chrome plating 3) make balance correction to ensure smooth operation. 4) Ratchet fixed version of the reel shaft. |

| 2印刷压辊 Pressure roller | 1)外径为Ø156mm 壁厚18mm 2)钢管表面研磨,镀硬铬。 3)做平衡校正,运转平稳。 4)印刷压辊间隙刻度盘手动调整调整范围1.2~12mm。 |

| 3送纸上下辊feeding roller up and down | 1)上辊:外径为Ø86mm厚壁钢管,配两个外径Ø136mm送纸环。 2)下辊:外径为Ø156mm厚壁钢管,表面研磨,镀硬铬。 3)送纸辊间隙刻度盘手动调整,调整范围1.2~12mm。 1) diameter for Ø 18 mm 156 mm wall thickness 2) steel tube surface grinding, hard chrome plating. 3) make balance correction to ensure smooth operation. 4)Manual adjustment of the gap dial of the printing press roller ranges from 1.2 mm to 12mm |

| 4钢质网纹辊steel type Anixo roller | 1)外径为Ø176mm。壁厚22mm 2)钢管表面研磨,压制网纹、镀硬铬。 3)做平衡校正,运转平稳。 4)网目数每组220线,可自选目数或陶瓷棍。 5)配合送纸系统气压式自动升降装置(送纸时网纹辊下降与印版接触,停止送纸时网纹辊上升与印版分离)。 6)网纹辊附楔块式超越离合器,匀墨、洗墨时方便快捷。 1) diameter of 176 mm Ø.22 mm thickness 2) steel tube surface grinding, pressing mesh, hard chrome plating. 3) make balance correction to ensure smooth operation. 4) mesh number: 220 lines per group, optional mesh number or ceramic stick. 5) cooperate with the pneumatic automatic lifting device of the paper feeding system (when paper feeding, the anilox roller falls in contact with the printing plate, and when paper feeding stops, the anilox roller rises and separates from the printing plate). 6) anilox roller with wedge type overrunning clutch, uniform ink, wash ink when convenient and fast. |

| 6橡胶辊 Rubber roller | 1)外径为Ø176±0.02mm。 2)钢管表面包裹耐磨橡胶,并做平衡校正。 3)橡胶中高特殊研磨,传墨效果好。 1) diameter for Ø 176 + / – 0.02 mm. 2) wear-resistant rubber is coated on the surface of the steel tube and balanced. 3)Rubber medium high special grinding, ink transfer effect is good. |

| 7相位调整机构 Phase adjustment | 1)行星式齿轮构造。 2)印刷相位采用控制及电动数字式360°调整。(运转、停止均可调整) 3)手动调整横向位置,调整距离±7.5mm。 4)在印刷过程中清洗印版后电脑记忆自动复位系统 1) planetary gear construction. 2) printing phase control and electric digital 360 °.(adjustable for operation and stop) 3) manually adjust the transverse position and adjust the distance to + / – 7.5mm. 4) computer memory automatic reset system after cleaning the printing plate in the printing process |

| 8水墨循环 | 1)气压式隔膜泵,供墨稳定,操作保养简单。 2)油墨过滤网,过滤杂质,水墨分离。 1) pneumatic diaphragm pump, stable ink supply, simple operation and maintenance. 2) ink filter net, filter impurities, ink separation. |

| 9印刷相位 固定装置 | 1)气缸式自动刹车装置 2)当机台分离或调整相位时,刹车机构限制机台转动,保持原有齿轮位置固定点。 1) cylinder type automatic brake device 2) when the machine is separated or the phase is adjusted, the brake mechanism restricts the rotation of the machine and maintains the fixed point of the original gear position. |

(三)四联模切开槽部die-slotting unit

操作控制Operation controller | 1)过纸间隙采用手调式快速间隙2)装有急停装置,以确保安全. 1) manual speed clearance is adopted for paper clearance 2) emergency stop device is installed to ensure safety. |

| 分纸/开槽模切刀座 Slitting/die-slotting | 1)优力刀厚度7mm,优质合金钢热处理齿形开槽机,专业厂家制造,确保质量。2)轴径为Φ156mm。表面研磨镀铬,移动平稳。 3)开槽、压线轮、位置轴向手动调整。 4)开槽中刀可以移动,适合生产大规格双片箱。 5)采用独特弹屑式除屑装置,降低成本,寿命长。 1) Die-slotting knife thickness of 7mm, high quality alloy steel heat treatment tooth groove machine, professional manufacturers to ensure quality. 2) the diameter of axle for Φ 156 mm.Surface grinding chrome, smooth movement. 3) manual adjustment of die-slotting, scorer wheel and axial position. 4) slotting knife can be moved, suitable for the production of large size double pcs box. 5) adopt unique dandruff removal device to reduce cost and prolong service life. |

(四)传动齿轮Drive gears

| 项 目Item 说 | 明Notes |

| 1主传动齿轮Main drive gears | 1)材质为:#45合金钢,渗碳淬火处理,研磨加工而成。 2)六级精度(与汽车传动箱齿轮同级)运转顺畅,噪音小,硬度HRC58~62,寿命长,10年以内基本不会磨损,可以达到长期印刷套准。 1) Material: 45# asteel, carburizing and quenching treatment, grinding and processing. 2)Smooth running, low noise, hardness HRC58 ~ 62, long life, can achieve long-term printing set. |

| 2免键连接环keyfree connection ring | 1)采用涨紧免键连接,可使轴与齿轮完成无缝连接,在大扭距使用时不会有间隙,安装及维修更方便,可使长期传动精度高,以保证印刷套准。 Adopt when tight no key links, can make the complete seamless connection shaft with gear, when used in large torque is there will be no clearance, installation and maintenance more convenient, can make the long-term high driving accuracy and to ensure that the printing alignment |

| 零部件 Spare parts | 图片 Picture | 功能 Function | 品牌 Brand name | 备注 Notes |

变频器Inverter |  | 主机5.5kw | 台达Delta | |

| 检查组件 Checking parts |  | 正泰Chint | ||

| 电器组件electrical appliance |  | 正泰Chint | ||

| 主电机 main motor |  | 15kw | 东光东力Dongli | 变频电机 Frequency motor |

| 齿轮减速机 Gear reducer |  | 0.18kw0.37kw | 东光南牛 Nanniu | |

| 匀墨 ink motor |  | 400w | ||

| 主体墙板 Main frame |  | 厚度thickness50mm | 精密铸铁 Precision cast iron | 日本三菱五面加工中心精加工 Japan mitsubishi five processing center finish machining |

| 传动齿轮gears |  | 厚度50mm | 45# | 剔齿、高频处理 Pick teeth, high frequency processing |

| 印刷辊筒 Printing roller |  | ɸ468mm | 45#钢卷制焊接而成,电脑动平衡校正,经研磨镀硬铬 45# steel coil welding, computer dynamic balance correction, grinding hard chromium | |

| 钢铁网纹辊 Anilox roller |  | ∮176mm | 动平衡校正,双盘双焊 Dynamic balance correction, double disk double welding | |

| 胶辊 Rubber roller |  | ∮176mm | 动平衡校正,双盘双焊 Dynamic balance correction, double disk double welding | |

| 底印辊 Bottom roller |  | ɸ156mm | 45#无缝钢管 45# seamless steel pipe | 动平衡校正,镀硬铬 Dynamic balance correction, with hard chrome |

| 轴承bearing |  | 万向牌Wanxiang | ||

| 气动元件Pneumatic component |  | 浙江天奥ZhengjiangTianao | ||

| 气动单项隔膜泵 Ink pump |  | 广州 布美兰 | ||

| 免键连接环 Keyfree link |  | 咸阳 Xianyang | ||

| 超越离合器 Overrunning clutch |  | 咸阳 Xianyang |